PRODUCTS

ADVANTAGES

A mechanical equipment company that integrates research and development, manufacturing, sales, comprehensive technical services, and import and export trade.

Reliable quality

Technology centered and quality guaranteed

Continuous innovation

Provide customers with valuable products and technological solutions

Wide sales range

Wide domestic market and sold to over 20 countries abroad

Eco-friendly

Eco-friendly and no any pollution,environmental protection

ABOUT US

Shangqiu Runda Environmental Protection Technology Co., Ltd

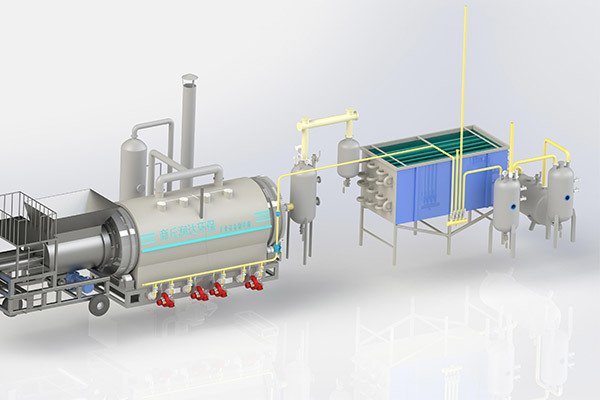

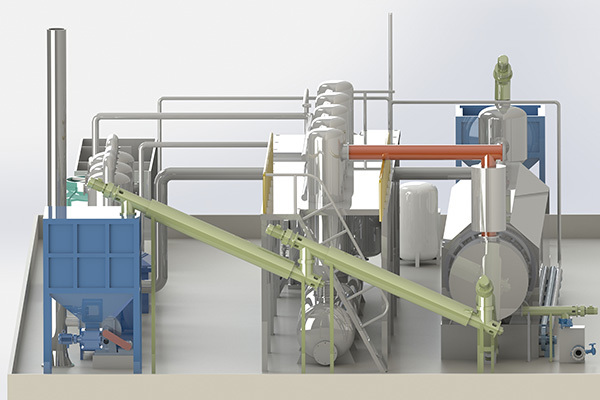

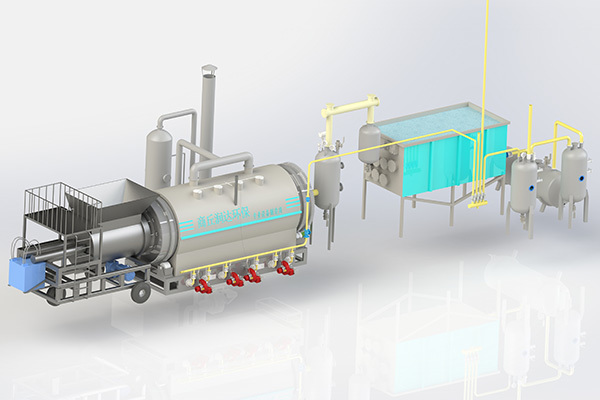

Shangqiu Runda Environmental Protection Technology Co., Ltd. is a mechanical equipment company that integrates research and development, manufacturing, sales, comprehensive technical services, and import and export trade. The company's main equipment is mainly divided into two categories: organic solid waste cracking and refining equipment, and waste oil distillation equipment

Make due contributions to the globalization, energy conservation, emission reduction, and integrated development of the energy industry.

NEWS CENTER

Real time updates on company news and industry trends, grasping cutting-edge information trends

2024-06-03

Crushing methods for solid waste

There are several different methods for crushing solid waste, each with its own advantages and disadvantages. Some common crushing methods include:

2024-06-05

What kind of oil is distilled from used motor oil

Distilling oil from used motor oil is a process known as oil re-refining. This process involves separating the different components of the used oil, such as contaminants, additives, and base oil, in order to produce a high-quality base oil that can be used in lubricants and other industrial applications.

2024-06-06

Characteristics of organic solid waste pyrolysis technology

Organic solid waste pyrolysis technology is a process that converts organic materials such as food waste, agricultural residue, and sewage sludge into useful products like biochar, bio-oil, and syngas through the application of heat in the absence of oxygen. This technology has several characteristics that make it a promising solution for managing organic waste and producing valuable bio-based products: